In 2008, Mosaic Corporation, a leading producer of potassium and phosphate nutrients for agriculture, began an effort to improve the productivity of its Wingate phosphate mine operation in Florida. On the market, the recovery of waste – the percentage of valuable material derived from mining – varies on average from 85 to 90 percent. Wingate operates at only 47 percent of oil recovery, given that there are concerns about the long-term viability of the mine. At first, managers expect a minimum of change. More equipped with excellent process training knowledge and efficient tools, including Minitab® Statistical Software, Six Sigma equipment increases productivity by more than 50 percent and has a financial impact of more than US$$ 12 million per year. The team's project also won the Prêmio de Excelência em Processo do Conselho Internacional de Qualidade e Produtividade.

Challenge

The Wingate mine was owned by several companies over the past two years, but it never lived up to their expectations. For this reason, it was dated in 1999 and remains the same since Mosaic was acquired and reopened in 2007. But the low recovery rates of the reopened mine cannot sustain a long period.

/Mosaic%20Corporation%20_%20Minitab_files/phosphateproducer.jpeg)

When the world's leading producer of phosphate nutrients for food decided to increase efficiency, the company relied on its critical data analysis to Minitab Statistical Software.

Phosphorus is extracted from the raw mineral by a process called beneficiation. In Wingate, the extracted ore was suspended in a well and then pumped to the beneficiation plant. The stones, fine clay and sand were separated from the phosphate stone by washing and penetrating. The phosphate stone is then treated with reagents to be more refined. In some part of the process, the mine was deficient. The Black Belts in Six Sigma Joe Gliksman and John Whitley felt it was time to apply their quality control methods to help the mine team increase profits, and they went to Minitab.

Mosaic has invested in Six Sigma since the company was founded in 2004, by the merger of Cargill and the International Minerals Corporation. In 2008 alone, its initiatives will involve more than 45 teams, more than 500 employees and will provide results of approximately US$ 25 million for the company. But when the Wingate mine team started working, expectations were minimal. “Managers expect a 2 or 3 percent increase in recovery taxes,” Gliksman said, “They told us that sustaining recoveries of 70% would be a miracle.”

How Minitab helped

Encouraged by the challenge, Gliksman and Whitley assembled a team that included all groups involved in the process, including engineers, equipment operators, mechanics, laboratory technicians, supervisors and even a company representative who provided chemical reagents for processing.

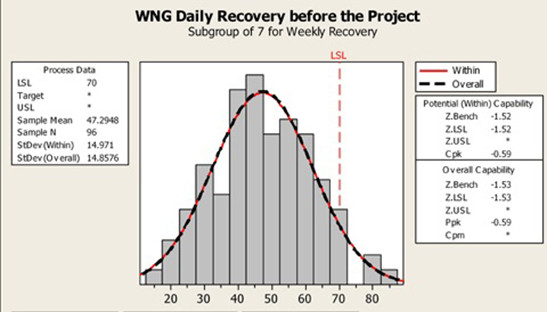

We will examine the mine's current operational data, which provides ideas about the performance of the process and how it could be improved. To analyze substantial management concerns about mine performance. “At the time goal, the recovery tax does not reach our goal of 70 percent,” Gliksman says.

The team discussed, mapped the mine flow process at the facility and conducted a cause and effect analysis to identify points in the benefit process with the greatest potential to increase recovery rates. To quickly obtain meaningful conclusions about how many different ideas work, the team uses Minitab's experiment design resource, which facilitates the simultaneous evaluation of several factors. Based on the results of this initial work, operators can immediately begin making alterations, and other opportunities for improvement are identified.

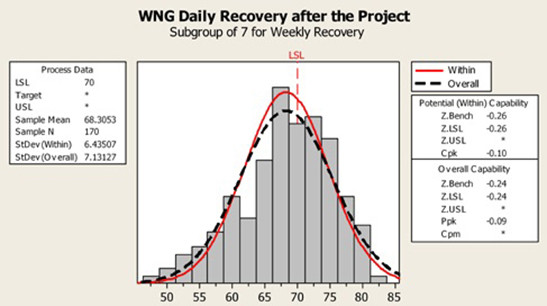

The team uses Minitab to run capacity analyzes before implementing improvements. Minitab makes it easy to see the significant impact of the project, as the average recovered stone jumped from 47 percent to 70 percent in less than 30 days. Other projects will further increase the recovery rates of the Wingate mine.

When equipment settings begin to impact, you will use Minitab's R&R Chart, Variation Test, and Control Chart functions to precisely verify two results, effectively confirm two incorrect settings, and demonstrate that they are being maintained.

Results

Thirty days after the project began, the waste recovery rate has increased from 57 percent to 68 percent, practically a 50 percent increase in concentrated phosphate stone production. The project has produced financial benefits equivalent to US$ 12 million per year, with US$8 million attributed to the increase in phosphorus production from the mine and US$ 4 million in cost savings due to the reduction in the quantity of reagent needed. per ton of processed ore. The project also caused a huge change in culture, because the mine operators could now see how the results of their training efforts improved or resulted. Reclamation projects will continue at the Wingate mine, with the implementation of other ideas increasing recovery rates to more than 80 percent. Thanks to the hard work of the team, with fundamental support of efficient data analysis tools, it is easier to understand the Minitab, a mine that has already been dated for a new life, together with a motivated work force, which continues to find new ways to improve processes.

Content originally published in: Minitab Blog

We are Software.com.br, Official Articulate Representative in Brazil and also a reference in technology solutions for the corporate world in Latin America. Count on our consultants specialized in Software Licensing, Cybersecurity, DevOps, Infrastructure and Data Analytics.

See more about Minitab on our site: Software.com.br

6 min reading

6 min reading